We meet with the client, designer, and the furniture dealer to establish the precise requirements of the project. We then determine the best solution for the job.

In the best of all worlds, we would always find a perfect match of style, finish, and size readily available and within budget. But in the real world, space, size, and dimensions often present problems. That's where our product knowledge and experience with the manufacturing process distinguish us from the rest.

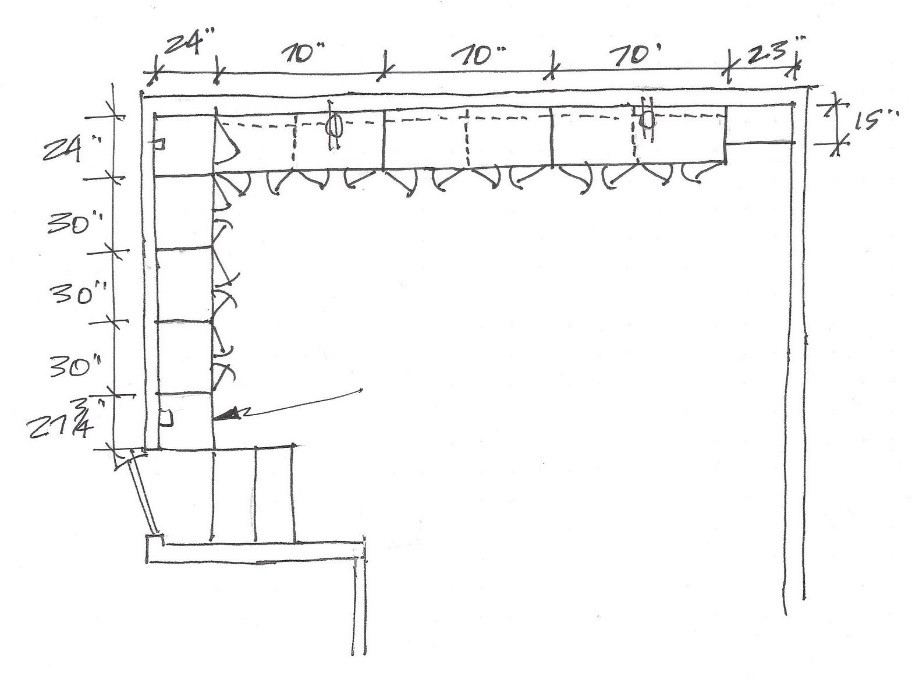

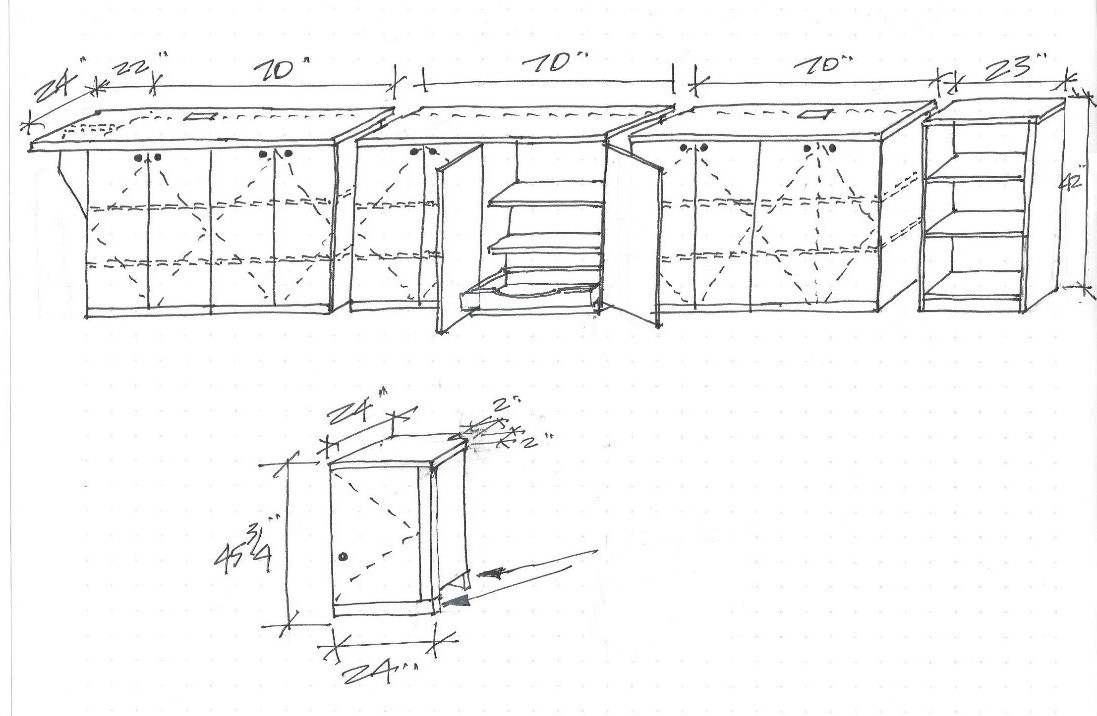

When the requirements for the job don't match up with any manufacturer's readily available solution, we create a solution. We may have an item customized by the manufacturer, or we'll custom design a new item that matches the customer's requirements.

We follow the job from start to finish, and we don't consider it finished until all issues are resolved. In short we do what ever it takes to be on time, within budget and with minimum punch list items...if any at all.

To us, service is as simple as that. Do the right thing.

Providing custom casework solutions for a prestigious university in Northern California...

From before...

...to after.

(Click to enlarge any of the images.)

Helping a social network create a space for collaboration, productivity and... you guessed it, socializing.

When a prominent tech company was looking for seating solutions they could reconfigure regularly for a variety of purposes, their designer turned to us for help. They wanted to put their feet on the seats to use their tablets on their laps, so we did deeper seats so they could do that.

For conventional seating positions, we added pillows so the seats were not too deep. They wanted seating that they could reconfigure... units without arms, units with arms on right and ones with arms on left as well as corner units. I could see them reconfiguring them and not having enough of one type... so I designed them to be non-handed. We ended up with 3 units, armless, corner (which is arm right or left) and an ottoman.

Click to enlarge.

But wait, there's more...

The CEO wanted the same features in his area but also wanted to be able to sit on the arms, so we widened the arms for his area.